The process of making music boxes is long, detailed and complex. Combining techniques that date back to the original period of the birth of the mechanisms over 150 years ago, with modern techniques of manufacture such as CNC machining. The following images explain the manufacture of the two main components, the musical comb and cylinder.

The rotation speed of the cylinder is controlled by an air brake. As the cylinder turns the pins set onto the surface of the cylinder lift and release teeth on the comb which generates the sound and melodies played by the music box.

The Comb

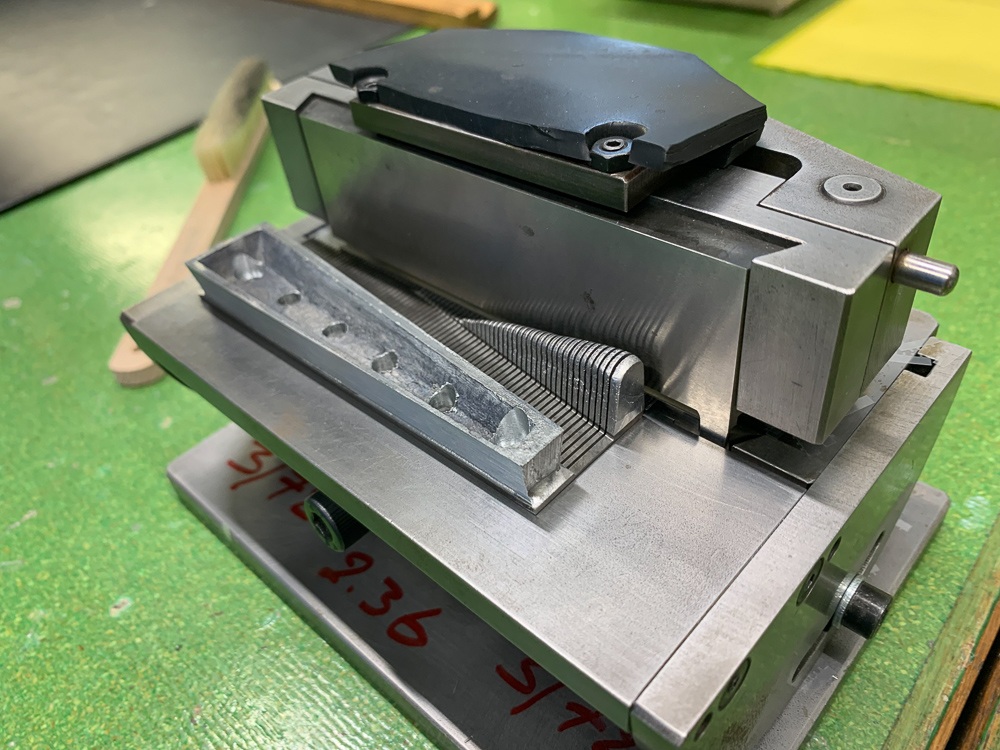

The comb is made from carbon steel which is hardened and annealed (slightly softened) twice. The following images are -non-exhaustive- of the process to manufacture and tune the comb. Each cylinder and comb is married together and referenced as shown in the image directly below to avoid a comb being incorrectly paired with the wrong cylinder.

1. The process begins with a steel plate which has the holes drilled through which are used when making the comb as well as locating it on the final music mechanism.

2. The comb is milled (cut) on one side in preparation for the lead and tin weight which will be added later for the low notes, as well as the section that will become the teeth.

3. The comb teeth are machined for the first time. The ends of each tooth are square and the steel has not been hardened. The time taken to cut the teeth is 45 minutes.

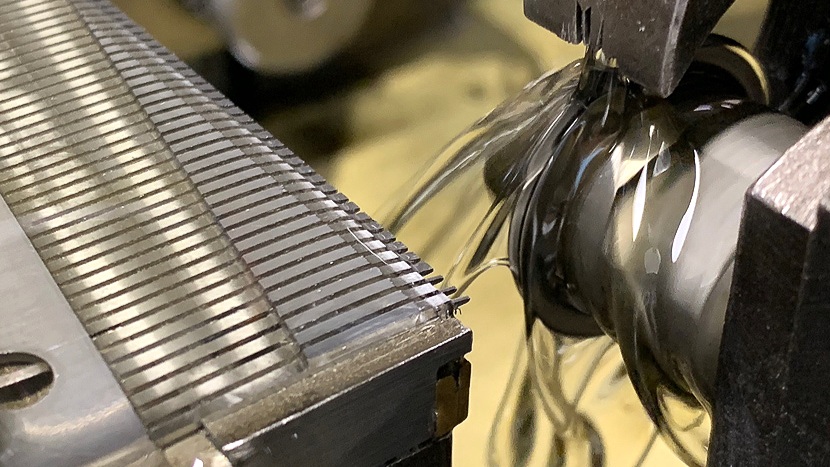

4. The plate is then machined a second time to generate the form of the teeth. The length of the teeth will be rectified at a later stage.

The circular cutting wheel that forms the final profile of the teeth rotates at a high speed and is flooded with cutting oil to protect the teeth from any deformation during the machining.

5. Once the teeth have been machined for the second time a heat resistant guide is slotted manually over the teeth in preparation for the first hardening process, held tightly in place with soft iron wire. This protects the comb from excessive deformation when the comb is heated red hot in an oven before being quenched in oil to render the comb glass hard.

When the comb is quenched in oil the surface becomes oxidised. It is then annealed for the first time in an oven to allow a small flexibility of the teeth so that it can be sandwiched tightly in a jig before being annealed a second time, correcting for any small deformation produced by the initial hardening process.

6. A solid lead & tin block is then soldered to the comb. The extra weight generates the lower notes on the comb.

7. The lead and tin mass is then partially cut through, the final cut is made later.

8. The foot, made from zinc (which accentuates the resonance), is then soldered onto the comb.

Unfinished and undecorated.

The zinc foot being soldered onto the comb. The long stick in the technicians left hand is the solder.

The foot is then placed onto the comb and the closed clamping tool heated to fix the foot and comb solidly together.

A series of combs being produced. Feet soldered and lead mass partially cut.

9. The comb is placed on a machine with a microphone linked to a digital read out which listens to the resonance of each tooth as it is plucked and indicates on the display the note. Then, each low note is manually adjusted/tuned cutting material from the lead/tin mass. The steel comb teeth are ground tooth by tooth on another machine removing material from the underside of each tooth.

10. Synthetic dampeners are added to the comb teeth to ensure a cleaner note and removing additional vibration that negatively effects the clarity of the sound.

Once the full row of teeth have the added dampeners a guillotine cuts off the additional synthetic material, shown above.

Three of the people involved in the process.