The Reason

Originally made in 1969 the first vertical clutch chronograph with automatic winding movement, produced in Japan.

Introduction/functions

The “Speed-Timer” has a chronograph centre seconds hand and 30 minute recorder at 6 o’clock, with day and date indication at 3 o’clock. The pushers for the chronograph are mostly integrated into the case centre at 2 & 4 o’clock.

The material of the case and bracelet is stainless steel SUS316.

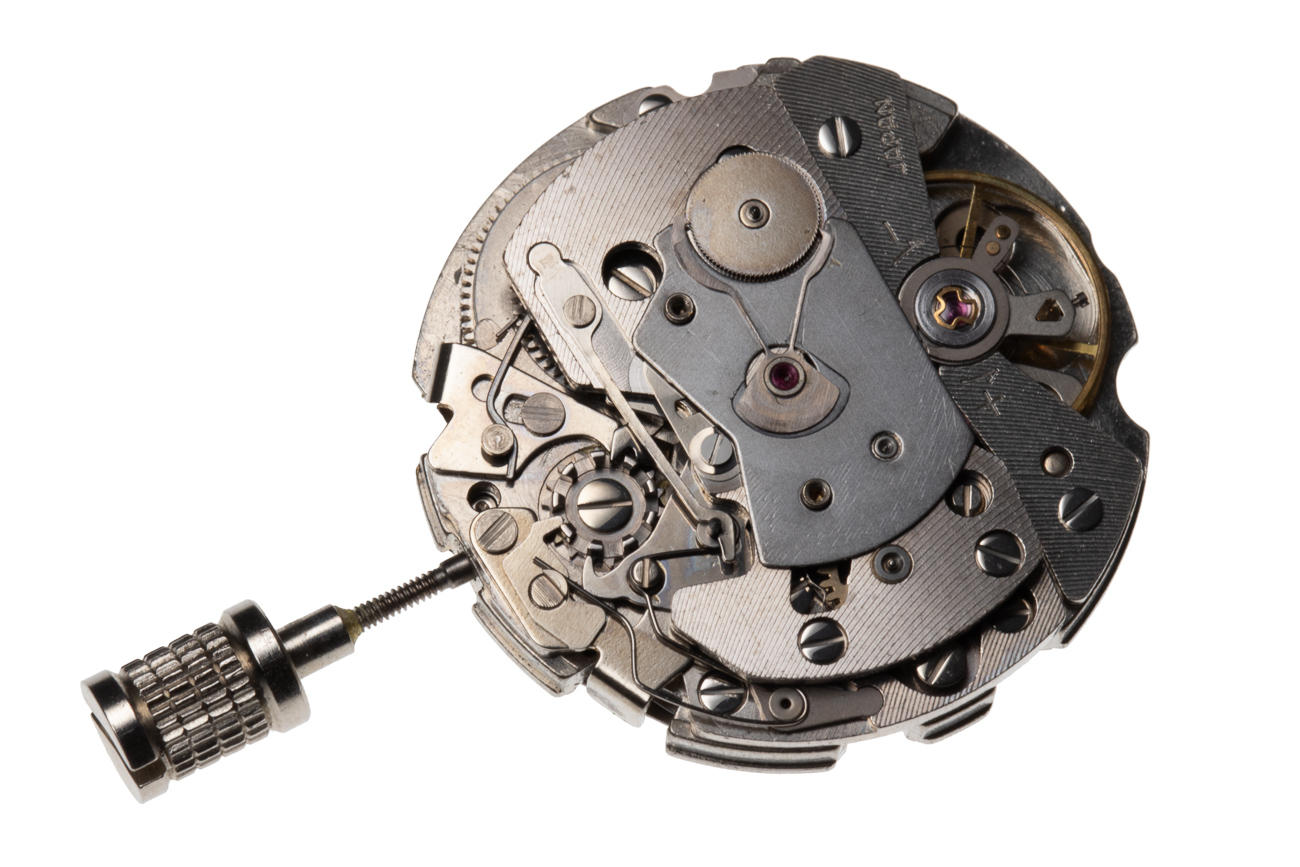

Movement shown with dummy winding crown.

The column wheel in view with 9 pillars.

An oversized diameter balance wheel with a traversing balance bridge holding the wheel in place.

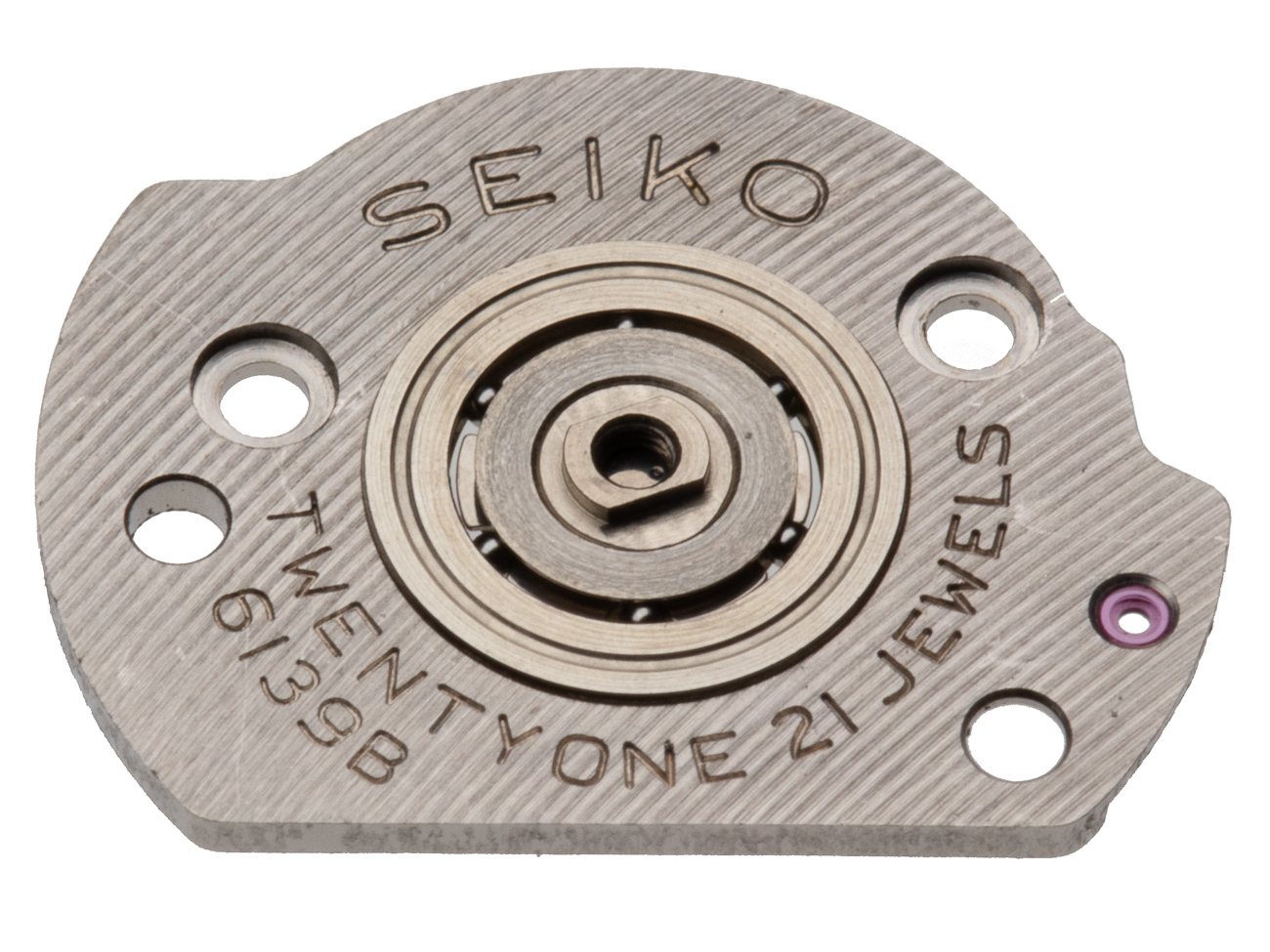

The automatic rotor removed.

Recto-verso of the rotor. Simply executed with the heavy tungsten weight riveted onto the steel central bridge with two large rivets.

Recto-verso of the bridge supporting the ball-race for the rotor. Because the ball-race mechanism drives the “Magic Lever”, directly from the centre of the watch, the ball-race is set into an addition bridge rather than being integrated directly into the rotor.

The rotor is screwed onto the ball race with a single screw and located by an irregular form locking it in place.

The offset steel pivot in the centre of the ball-race which drives the automatic “Magic Lever”.

With the ball race bridge removed, the winding “Magic Lever” which pushes and pulls the fine toothed ratchet wheel is viewed. The off-set steel pivot drives through contact with a circular jewel that is set into the “Magic Lever”, the system winds the barrel when the rotor winds clock or anti-clock wise.

The automatic bridge removed, now showing the bridge which covers and holds in place the majority of the chronograph mechanism.

With the large chronograph bridge removed the chronograph mechanism can be viewed.

The vertical clutch mechanism.

The large steel lever in the centre is the hammer piece which returns to zero the chronograph seconds and minute wheels carrying their hands.

The calendar mechanism with the day disc removed.

Summary

An industrially designed, mechanical chronograph, made with the intent for precision, strength, volume and longevity. Combined with ease of assembly and future repair. The large oversized balance wheel assures precision timekeeping aligned with much earlier designs of movements. The balance bridge traverses the wheel and is held by two screws, one on either side of the balance wheel, making a rigid assembly, (this is more seen today than at this period). Other elements lending to the overall pragmatism of the design are the rotor, simply executed with the heavy tungsten weight riveted on the steel central bridge, with two large rivets. As well as the relatively small number of components found in the calibre compared to conventional chronographs. The vertical clutch system was adopted to reduce the number of components overall and has become today a popular system being used in new modern calibres.

The movement designed half a century ago, was very much ahead of its time.