The Reason

The most simple, recognisable and iconic of all Breguet wristwatches.

(Launched in 2006)

Functions: central seconds, minutes & hours with date.

Winding automatic Power reserve 55 hours Calibre 777Q Jewels 26 Frequency 4Hz Escapement Swiss straight-line lever / Silicon Balance-spring Flat / Silicon / freesprung Oscillating weight 18 Carat gold Number of components 243 Case Metal 18 carat yellow gold Sapphire caseback & bezel Case diameter 38mm Case thickness 8,8mm Water-resistant 30m

Each Breguet ‘Classique’ watch has a unique serial number which is found both on the dial and case back, then recorded in the company archives.

The case back is pushed onto the centre using a case press. Below, the case back is removed showing the movement held in its movement ring in-turn secured in place in the case centre by 3 casing screws and bridals.

The dial is made in 18 carat gold, the guilloché decoration executed on rose cutting engines operated by hand. The dial below was photographed before the serial number was added. The serial numbers are printed after the dials are made and once the dial is associated with the case, that is already engraved.

Conventionally guilloché dials were made from silver, less so from gold, primarily because the dials are more commonly finished in a silver colour. Once the gold dial is cut, it is plated with silver, printed and a thin protective coating added to avoid any tarnishing of the silver over time.

Historically Breguet has used a secret signature on the dial as a means to protect the authenticity of each watch. In early examples there was a single signature engraved to one side of the number 12. With modern Breguets’, for equilibrium and added security the Breguet signature is engraved either side of the ‘12’.

The dials are machined, including the dial feet, from a single disc of 18 carat gold. Four dial feet assure extra rigidity on the rose cutting engines when the dials are being cut, as well as security when sitting on the movement and movement ring. They are heavier than many conventional dials because of the density of the material and the large volume of the gold used.

The style of the hands have become known as Breguet, and have been used by many other manufactures since their original incarnation.

These shown, are made in hardened and tempered steel, polished then thermically blued, (as were all original blued hands on both watches, clocks and marine chronometers). Today companies will frequently use softer metals to produce the hands more easily and then varying methods for colouring them).

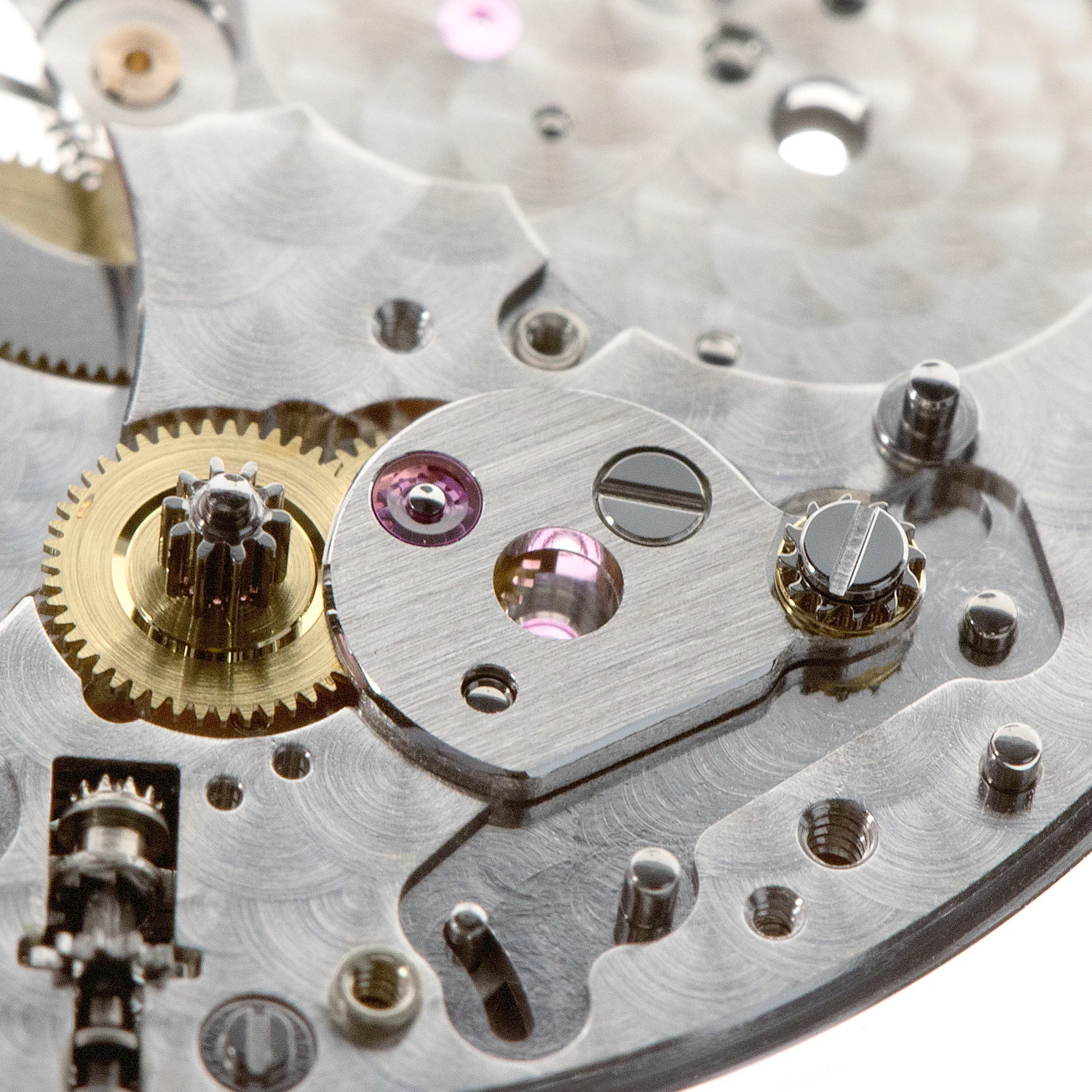

Movement calibre 777Q The winding is automatic, the rotor winds both clockwise and anti-clockwise. The power reserve lasts for 55 hours, the barrel is fully wound after approximately 3 hours of wear upon the wrist (on average). There are 26 synthetic rubies set into the calibre. The balance vibrates at a frequency of 4Hz. The escapement is a Swiss-lever made in silicon. The balance-spring is flat, also made silicon and free-sprung. The oscillating weight is made in 18 carat gold.

Above (right): the movement with the rotor removed, highlighting the Geneva stripes and the forms of the bridges.

The lower step circling the movement is to make space for the rotor weight. The balance spring is free sprung, with no index to regulate the length of the balance spring by adjusting its effective length. Instead the regulation is made through the adjustment of the timing screws on the balance wheel.

The 18 carat automatic rotor weight pivots on a ball race held in place by 3 screws. The Guilloché is executed by hand with a rose cutting engine as with the dials. The Breguet name is machined. The rotors are delicate, therefore during the assembly process a working/dummy rotor is used until the watch is finished. Then once complete the dummy rotor is exchanged with the definitive gold version. (At the end of this deconstruction there are images of how the components, like the rotor and dials are stocked after they are produced and before they are assembled).

The balance wheel is made from glucydur, an alloy made from a mix of beryllium, copper. It is hard, stable, and highly resistant to deformation. The balance spring from silicon.

The balance wheel and cock are screwed onto the mainplate, located by two steady pins. The form of the balance cock follows the ‘S’ curve of the train bridge.

The balance assembly: comprising of the balance wheel, four regulating screws, safety roller and impulse jewel (hidden), Incabloc shock protection, stud, stud holder, cover plate and screws, balance cock with end-piece securing plate and screw.

Through the balance wheel can be seen the underside of the stud holder, carrying the end of the silicon balance spring. The circular steel plateau with the impulse jewel pushed into it. Through this jewel, the energy is transmitted from the Swiss lever to cause the balance wheel to oscillate.

An exploded view of the balance and escapement. The elements which are blue are manufactured in silicon. (The use of silicon renders the parts lighter than their conventional steel counter parts and are non-magnetic).

The movement with the balance assembly removed.

The Swiss lever and its bridge removed from the watch.

The golf club head in the centre is linked to the setting mechanism and pushes against the balance wheel to hack the seconds in setting position so the seconds hand can be stopped.

The colour purple of the silicon escape wheel changes depending on the angle the light catches it, sometimes appearing black. At the end of one arm, on the rim of the wheel is a precision etched (DRIE) ‘Breguet’ signature. Virtually impossible to see at low magnification.

Recto-verso of the train bridge.

An exploded view of the train bridge and wheels, including the hacking mechanism for the balance wheel.

The train bridge removed, showing the gear train with direct seconds drive. (The escape wheel pinion is leaning away from the centre wheel because the train bridge has been removed).

The design of the wheels, notably the arms derives from the original Breguet pocket watches made two hundred years ago and are indicative of the Breguet DNA.

An exploded view of the barrel bridge and part of the automatic winding mechanism.

The assembled barrel bridge with the train removed.

The inversed steel wheel below is the first to mesh with the rotor pinion, winding up the automatic mechanism.

Recto-verso of the barrel bridge. One of the springs set into the bridge pushes on the click for the ratchet wheel. The second pushes an intermediate winding pinion out of engagement when the winding is being executed by the automatic mechanism and not through the winding crown.

The barrel bridge removed leaving only the assembled barrel and part of the automatic winding mechanism.

(Below) In the foreground the full hacking system for the balance wheel, starting on the left from the setting lever protruding through the main-plate. Behind it, the first, star-shaped toothed pinion (known as a Pelton gear)meshes with the lower level of the gold coloured reverser wheel. Allowing this level to turn in only one direction. The pinion behind it then meshes with the pinion set into the barrel bridge which in-turn winds the ratchet wheel and mainspring. The rotor winds the watch as it rotates in both directions.

Multiple views of the empty case

The system holding in place the strap is through an extended screw bar traversing the two shoulders with an additional locking screw tightening into a small ‘V’ section near the slotted head of the screw.

Summary

The watch construction is solid, proportionally balanced and holistically designed. With a well thought out philosophy of build which traverses all levels of the piece. Traditional blued steel hands, solid eighteen-carat gold guilloché dial and a slim but solid and technical calibre. Mixing modern materials such as silicon, with conventional ones as well as a DLC coated barrel, an effective classically inspired but strong modern movement. The decoration includes hand-finished internal corners, Geneva stripes, mirror finished steelwork and amongst the strongest and well-finished screws produced today. The wheels, although not viewed in the assembled calibre follow the companies original DNA. The free-sprung silicon balance spring, Swiss lever and escape wheel contribute to taking the calibre technologically one step forward. Retaining and perpetuating the original Breguet secret signatures not only on the dial but escape-wheel and on other parts, emphasises the detail of thought that has gone into the development process.

Tooling

The case back is pushed onto the centre of the case and sandwiches in place a silicone seal assuring the watch remains water resistant. To remove the caseback with out damaging the flooting on the vertical section of the case centre, a knife edged blade is used at a specific point at 9 oclock to lever the case back off.

The calibre in the movement holder

Specialised containers

The spring loaded container used for storing and transporting the rotor prior to it being added to the finished movement.

Although the hands are made from tempered hardened steel, the blued finish is delicate and they are stored in non-acid based papers and envelopes until they are assembled.

The tailor made movement containers.

A selection of the tools used to assemble the calibre.

Filmed deconstruction of the new model 5177

with Henrik Korpela The K&H Watchmaking Competence Centre, Le Locle

Classique 5177 Grand Feu Blue Enamel Dial

To learn more about Breguet www.breguet.com