The Reason

An original and newly patented constant force mechanism driving a 60-second tourbillon with jumping seconds.

The Constant Force Tourbillon is part of Arnold's Royal Collection. In a conventional tourbillon or simple time keeper the accuracy of the watch is partly dependent on the isochronism of the balance as the power reduces and the mainspring unwinds. (*Isochronism meaning; regardless of the amount of power transmitted to the balance and the amplitude of the balance wheel, the period of the oscillation remains the same allowing the movement to run down evenly assuring precision time keeping).

Instead of power from the mainspring being fed directly to the escapement as can normally be found in a traditional tourbillon or simple timepiece, the mainspring charges/winds a small ‘balance style’ spring which in turn releases a even and consistent amount of power to the escapement/tourbillon, each second. In this way it is the small balance style spring powering the escapement rather than directly from the mainspring.

The device also drives the jumping seconds hand. When the power from the mainspring drops below that which is required by the constant force mechanism, the movement stops rather than running at a lower precision. The constant force device rotates once per minute and optimises the precision through the constant/even power to the escapement. The 60-second tourbillon averages out gravitational errors on the escapement by constantly rotating it through 360°.

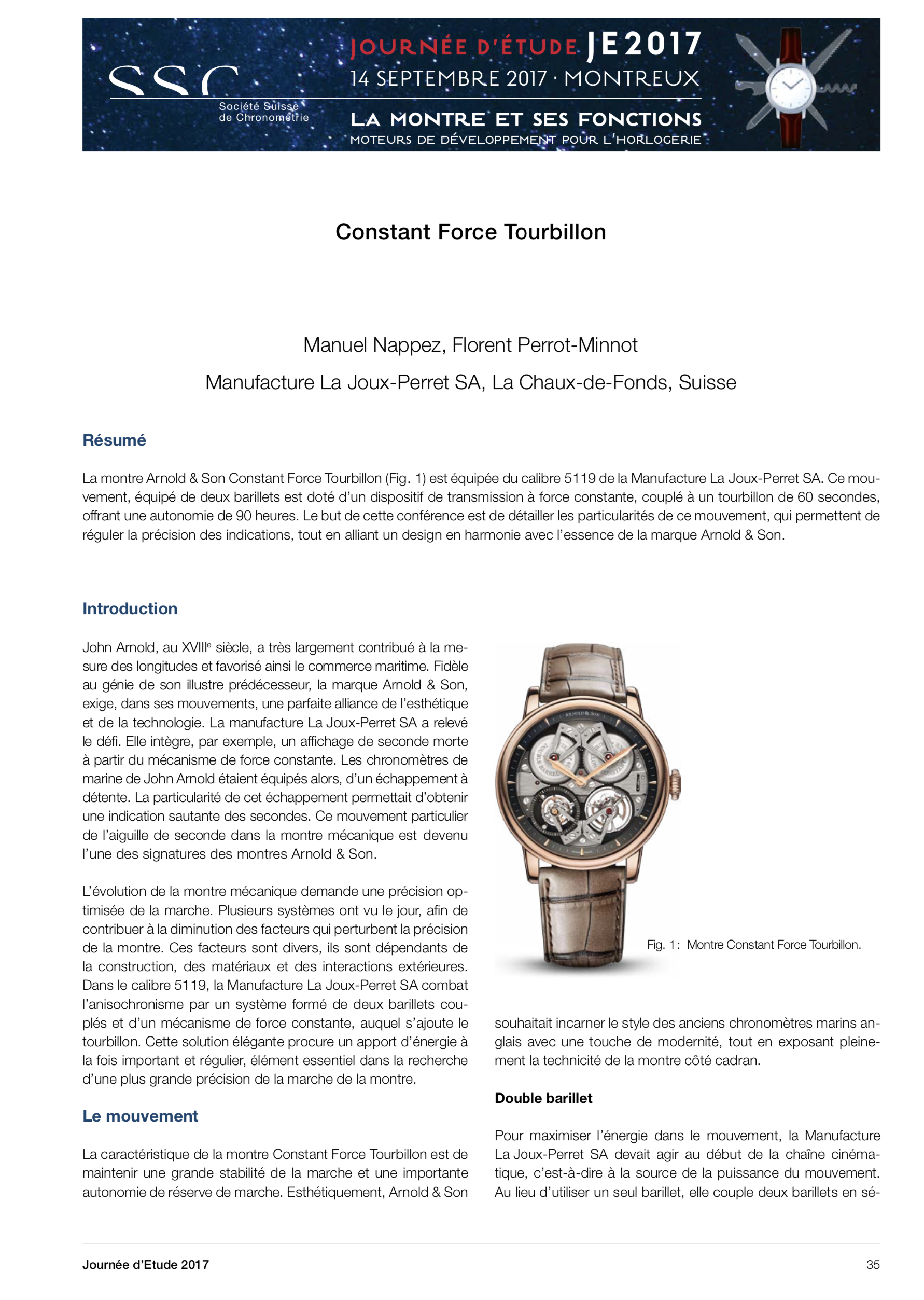

18-carat red gold case, diameter 46 mm, domed sapphire with anti-reflective coating on both sides, see-through sapphire case back. Water resistant to 30 m.

Movement AS5119, hand-wound, 39 jewels, diameter 36.8 mm, thickness 6 mm, power reserve 90h, double barrel, 21,600 vibrations/h. Movement decoration: nickel-silver and steel movement, palladium treated bridges and NAC grey treated main plate. Hand-angled bridges with polished edges and straight grained surfaces, screwed gold chatons, screws with bevelled and mirror-polished head. Tourbillon cage: mirror-polished with hand-angled polished edges and circular satin-finished surfaces.

The project was launched in 2013 and presented at Baselworld for the first time in 2015.

The time the watchmaker spends on the assembly of each watch is approximately sixty hours. This includes pre-assembly, decoration, assembly, adjustment, controls, casing etc. This work is spread over thirteen weeks, eight weeks to build the movement then five weeks for casing, checks and tests. This excludes the time of production and decoration of the parts in the kit that the watchmaker receives.

Profile showing the stepped design shoulders and the Arnold winding crown with logo.

Compression case back removed

The movement is removed from the case by taking off the bezel and removing a movement ring hidden under the bezel and dial which holds the movement in place.

The primary ratchet wheel with partially hidden click at 12 o’clock

Anthracite open dial with applied battons. The dial is held sandwiched between the bezel and movement ring.

The movement removed from the case and dial. The 3 hands remaining in place with the seconds chapter ring still held by its three screws.

The Tourbillon

The constant force mechanism (seconds chapter ring removed)

The upper bridge holding the Tourbillon in place removed.

Below the exploded view showing the assembly position and bridges that support the Tourbillon and the constant force mechanism.

The tourbillon removed

The Tourbillon removed from the movement.

Recto-verso of the Tourbillon cage with exploded view

The upper bridge removed from the constant force mechanism assembly.

The constant force mechanism removed from the calibre.

The constant force mechanism (9.2mm in diameter) which is powered by the force from the barrels. Once the spring seen below is partially armed, every second the Tourbillon is impulsed from the energy released from this spring through the assembly, both transmitting energy to the Tourbillon and producing the jumping seconds action on the off centre seconds hand.

Exploded views showing the assembly of the constant force mechanism. The mechanism, as with the complete movement is assembled and adjusted manually.

A selection of components from the kit the watchmaker receives to assemble the constant force mechanism. The total number of components for the movement is 255.

Recto-verso of the bridge and fixed wheel which holds in place the constant force mechanism.

The lower bridges for the Tourbillon and the constant force mechanism removed. The above skeletonized wheels are both ratchet wheels for the two barrels.

The two train bridges removed showing part of the setting train and the gear train. All of the large bridges and main-plate in the movement are made from German Silver (maillechort) and the smaller in steel.

The two train bridges from above. The straight graining and angling of the bridges are executed manually.

An exploded view of the setting and winding mechanism.

With the bridges removed the full setting mechanism is visible and the click for the ratchet wheel can be seen unobstructed at 9 o’clock. The second barrel is wound by the force of the first, which transmits the power directly from the teeth on the barrel via a pinion (shown between the two large steel wheels) and in turn winds the second mainspring via the larger of the two steel wheels.

The bridges for the lower pivots of the two barrels.

The two ratchet wheels which wind the mainspring/barrel arbours are seen below the main-plate. The ratchet wheels have square holes in their centres which marry to the barrel arbours. At this stage the majority of the calibre is dismantled on this side of the movement. The setting mechanism is usually left in place during servicing.

Dial side of the movement with the two barrels still in place.

The surface of the two barrels are circular grained after the chemical etching of the details shown.

All wheels removed with the remaining bridges in situ.

In total there are over 255 components in the finished calibre, below there are multiple assemblies which remain complete. The Tourbillon cage and constant force mechanism alone contain 60 pieces.

Summary

The Arnold & Son Constant Force Tourbillon is a further example of how a complex horological concept can be taken and made simple. As mentioned on the previous Arnold & Son deconstruction, making a simple concept complicated is easily done, the opposite is far more challenging. With this calibre both the movements construction and architecture is well thought through, the overall finishing is clean, fine and balanced.

A series of bridges fixed to polishing jigs waiting to be either straight grained or polished by hand.

Le document ci-dessous a été publié en 2017 par Arnold & Son

To learn more about Arnold & Son